MistBuster

MistBuster 850 Electrostatic Mist and Smoke Collector - 850 CFM

MistBuster 850 Electrostatic Mist and Smoke Collector - 850 CFM

No se pudo cargar la disponibilidad de retiro

An electrostatic precipitation air cleaning system for the source collection

and removal of smoke, mist and metal particle contaminants produced from

machine tool coolant fluids. In the MistBuster family of products, the system

supplies a higher spindle speed and coolant pressure (600–1,500 PSI).

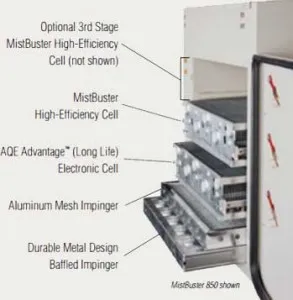

The MistBuster 850 five-stage air filtration system features Air Quality

Engineering, Inc.’s patented AdvantageTM electronic collector cell and

one or two high-efficiency electronic collector cells. The electronic

collector cells provide a collection efficiency up to 99.4% on all submicron

particles. An optional fifth-stage HEPA filter offers filtration efficiency up to

99.97%. Airflow is variable and controllable up to 850 CFM. Easily switch

between water-soluble or oil-based machine tool coolants using Air

Quality Engineering, Inc.’s patented variable voltage coolant selector.

Applications:

- Metal machining

- Grinding/polishing

- EDM mist collectors

- CNC machining

- EDM Laser Marking/Engraving (excluding Cast

Next Generation Technology

While electrostatic mist collectors provide a high-efficiency filtration system for mist and smoke collection, they sometimes require frequent washing of the electronic filter cell. Cell washing is required when collected contaminants cause a short circuit in the cell. Using next-generation technology, individual test sites have seen service intervals increase from monthly washing, to yearly washing of the collector cells. Individual results will vary.

MistBuster’s patented next-generation technology aims to minimize the short circuits which require the washing of the electronic filter cells through:

- Floating ionizer contact

- Proprietary ceramic insulator design

- Enhanced cell end plates

- Patented collector fin design

- Internal cabinet “air break”

- Patented variable voltage coolant selector

(Patents #6428611 and #7717984)

Product Sheet

MistBuster Series Brochure

The MistBuster® family of products is designed for the control and filtration of smoke, oil and coolant mist generated in CNC machining applications. The MistBuster® brand, manufactured by Air Quality Engineering, Inc. (www.air-quality-eng.com) has been an innovative product in the air filtration industry. Its multi-patented design provides superior performance in a cost competitive, compact and flexible package. The MistBuster® mist collector has been refined over many years of field experience culminating in its Next Generation design that features a decrease in its physical size, while improving its filtration efficiency, lengthening the time between electronic collector cell service and increasing the reliability of all components.

The MistBuster® features a variable speed motor control allowing the user to dial in the MistBuster® to the minimum required airflow for your machine tool cavity. This results in maximized energy efficiency filter life reducing maintenance.

Air Quality Engineering, Inc. investment in metallurgy research resulted in the creation of a state of the art ionization wire alloy that minimizes breakage and still achieves excellent ionization. This proprietary alloy and design has greatly reduced the need to replace ionization wires.

The MistBuster® product has been carefully designed to minimize vibration. Dynamically balanced impellers mounted on rubber isolation mounts mitigates the possibility of transmitting vibration to your machine tool, protecting the integrity of your precision tolerances.

The next generation of MistBuster® electrostatic units utilize patented "floating contact" design and "air breaks" on contact boards to provide a more robust solution to the problem of short circuits due to coolant tracking. This means more up-time and less maintenance.

MistBuster® patented coolant selector switch easily adjusts the high-voltage used with its collector cells to compensate for varying dielectric qualities of coolants and oils.

Next Generation MistBuster® is designed to protect the electrical components - all electrical components are completely removed from the air stream and are completely isolated in a separate compartment to prevent fouling from dirty air. Easy access is gained to electrical components in mere seconds via quick turn fasteners, eliminating the need to remove dozens of screws.

The MistBuster® family of air filtration products includes both disposable media systems as well as electrostatic precipitators. The MistBuster® product line has expanded to include centralized media systems for those who prefer a larger, central system that can be ducted to multiple machine tools, or to handle those larger machine tools that are not well enclosed.

With a variety of mounting options, model sizes and available configurations, there is sure to be a MistBuster® solution that will meet your specific requirements.

Videos